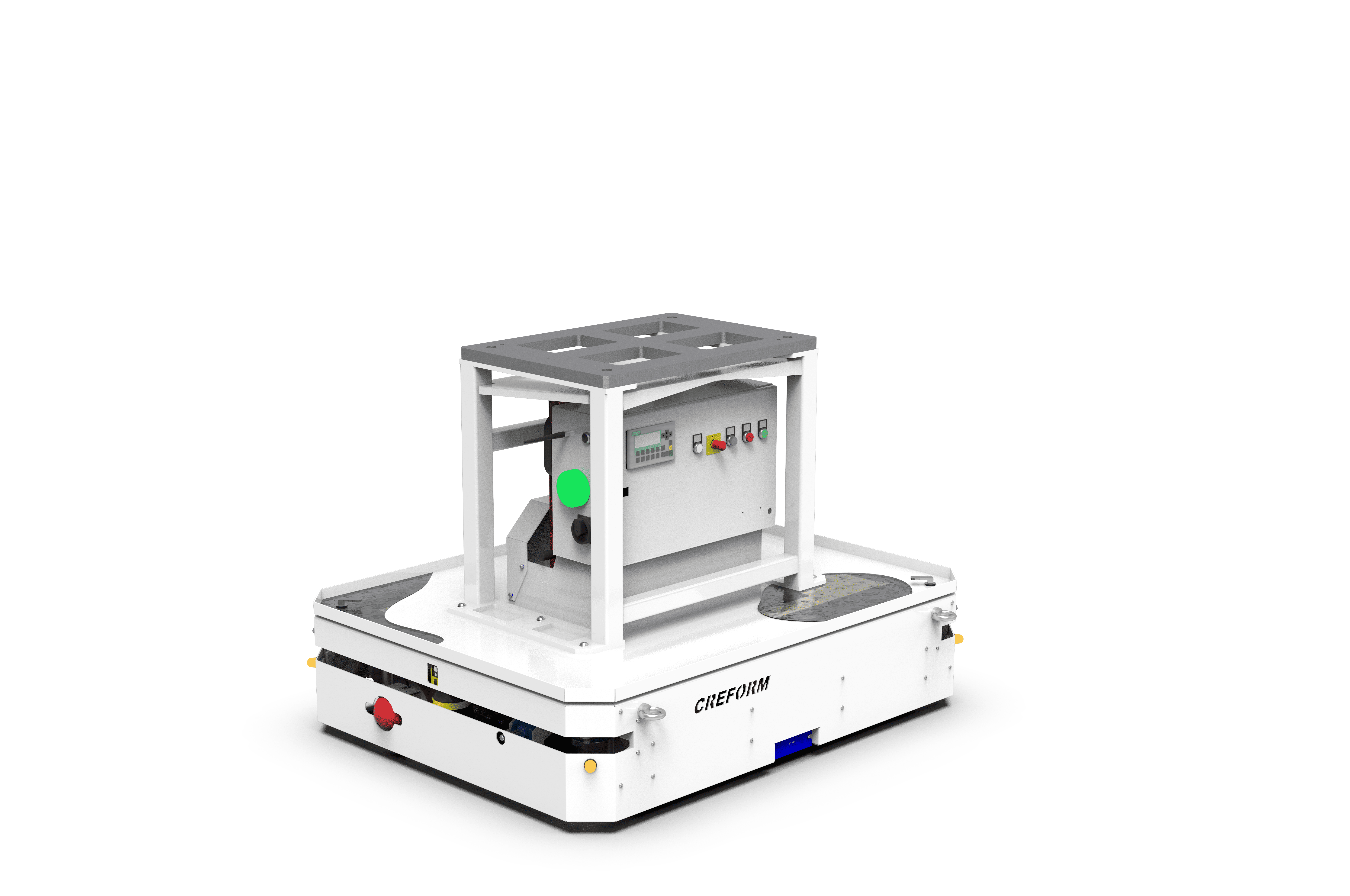

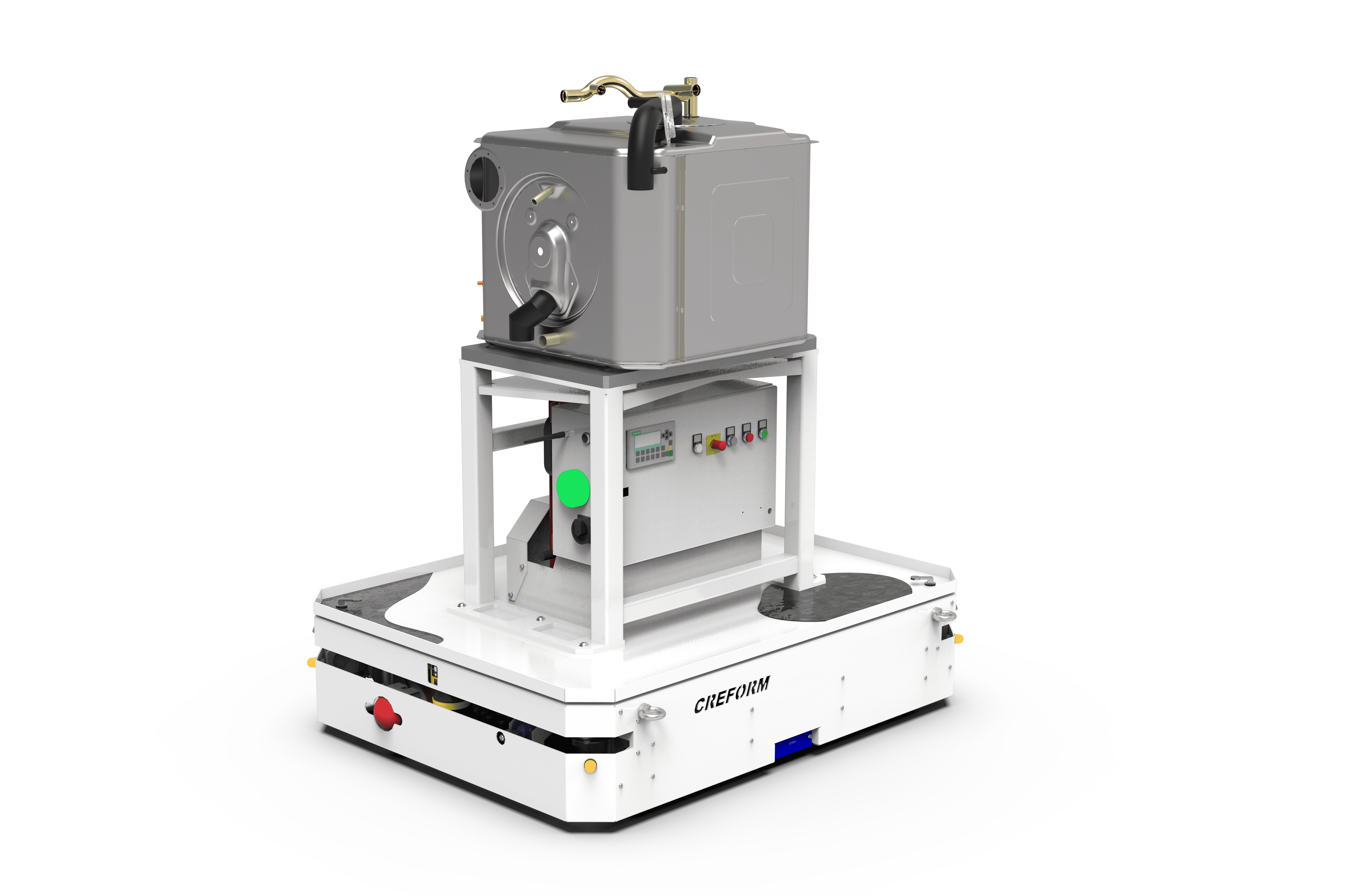

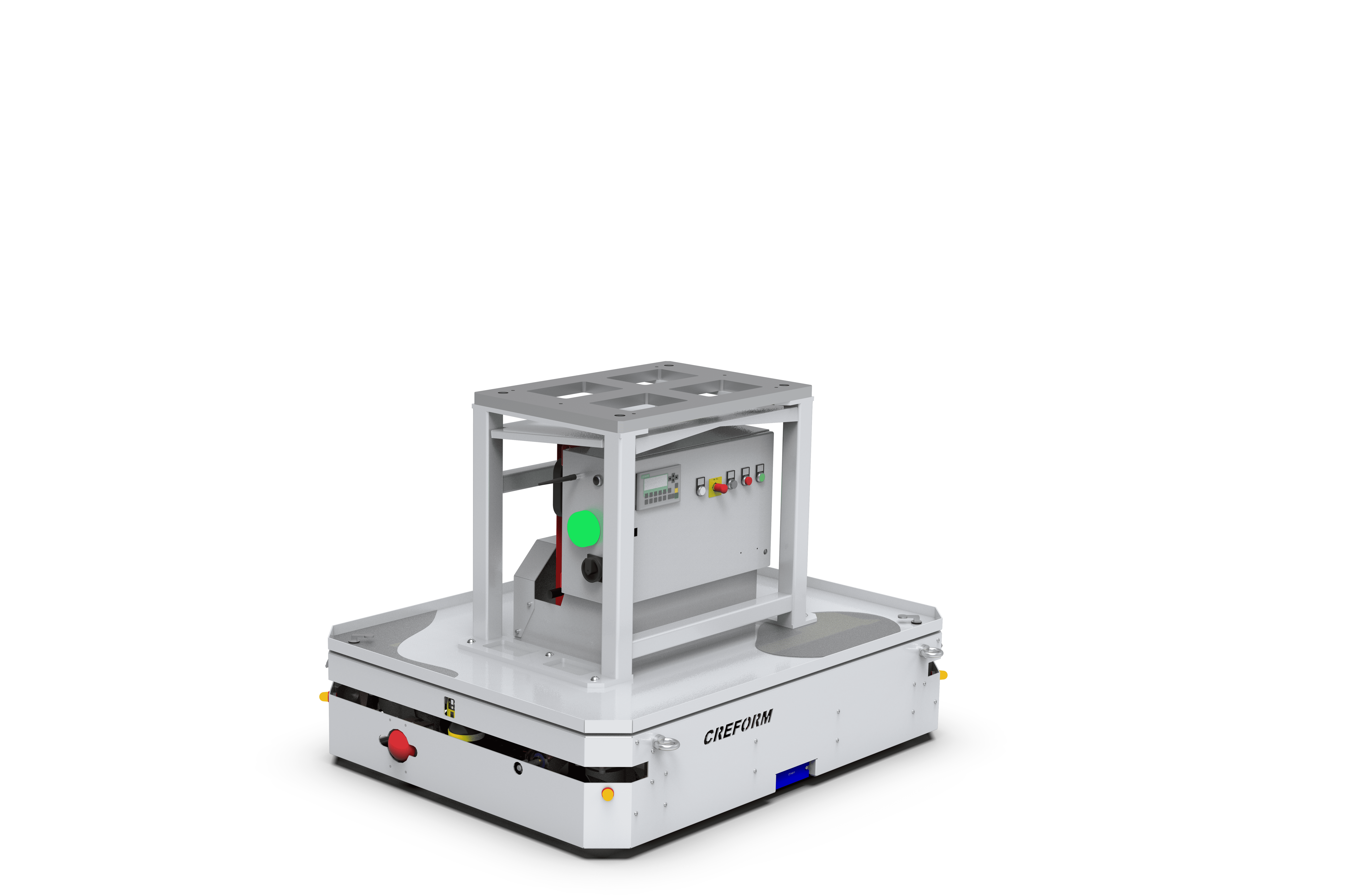

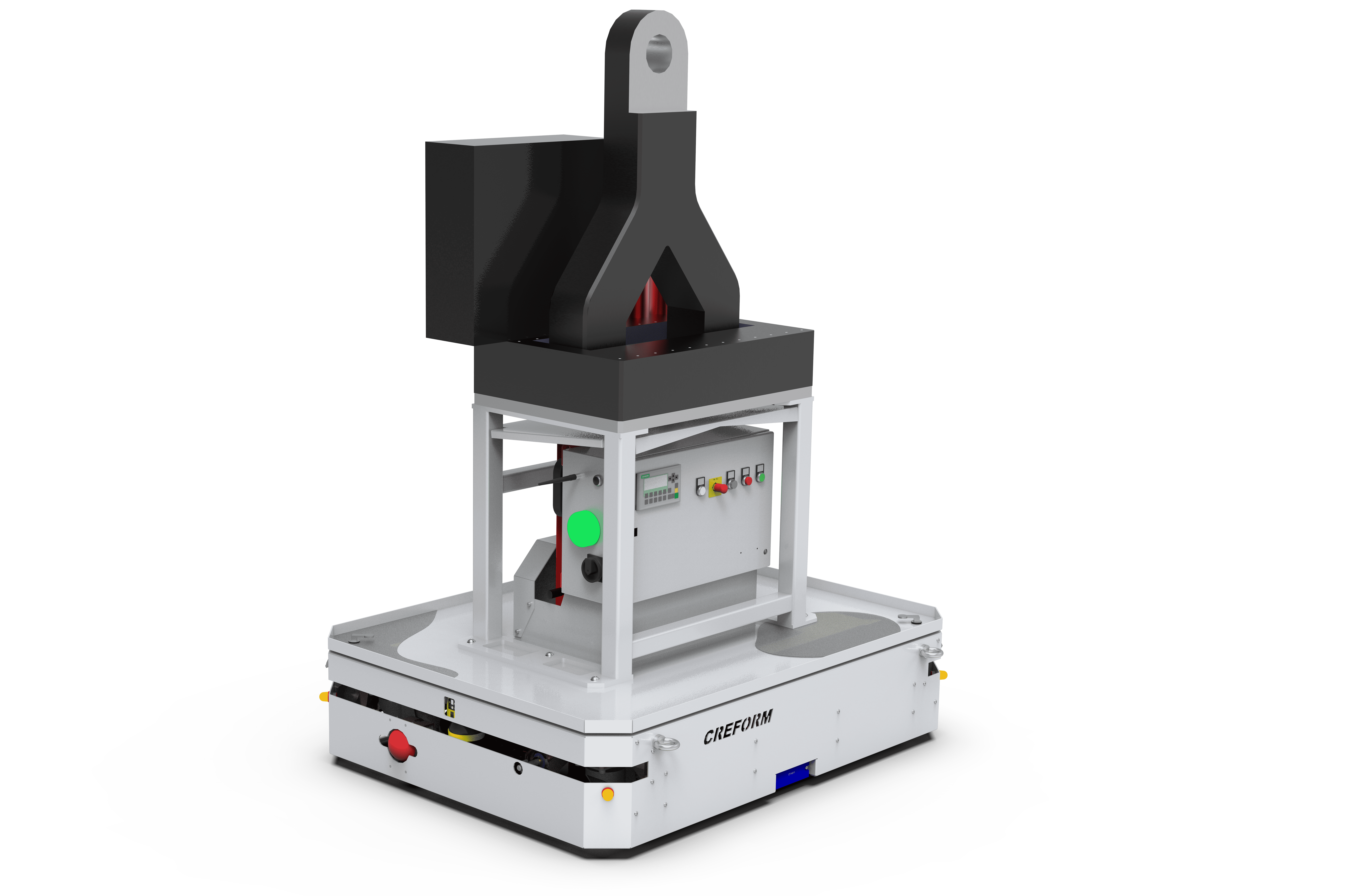

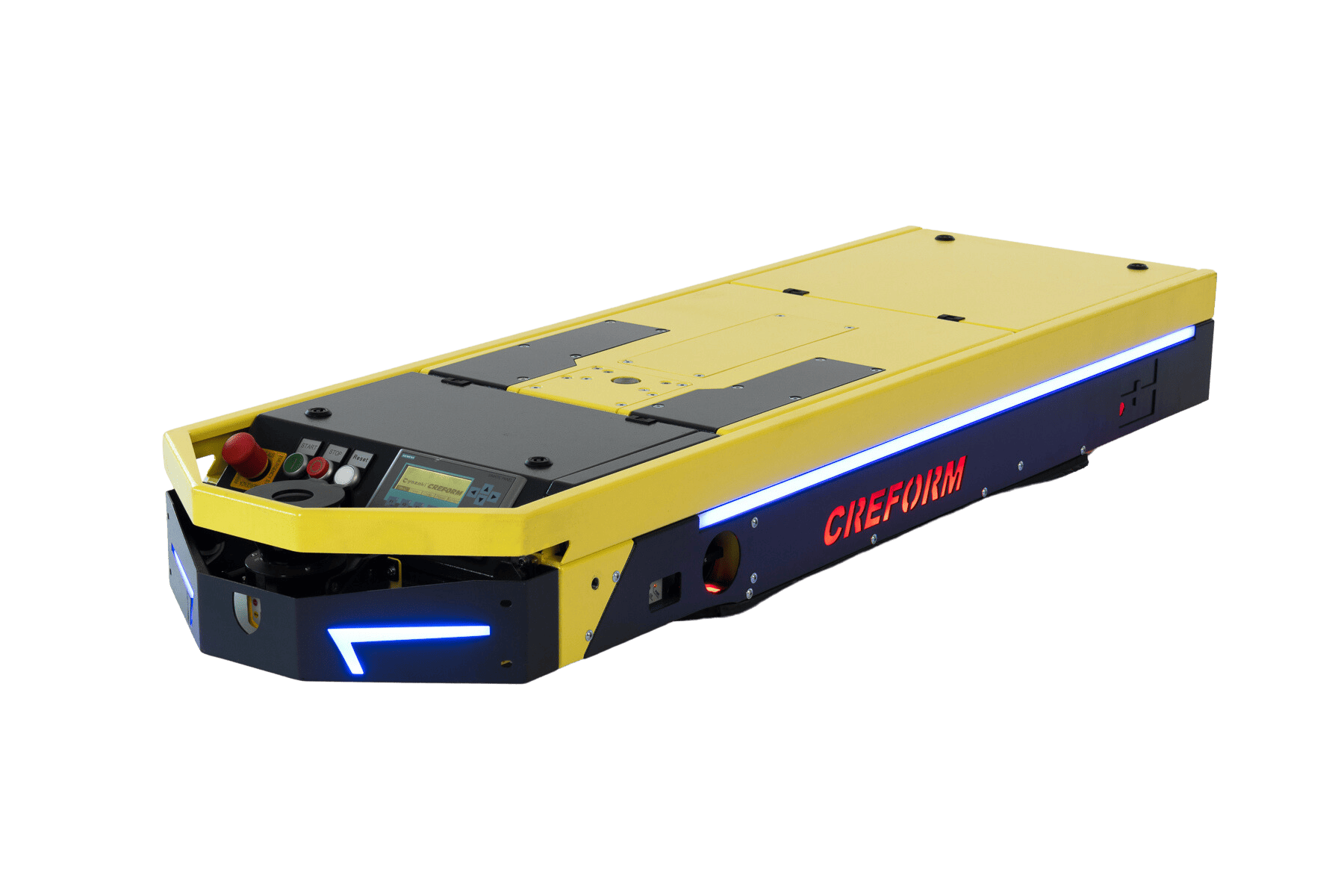

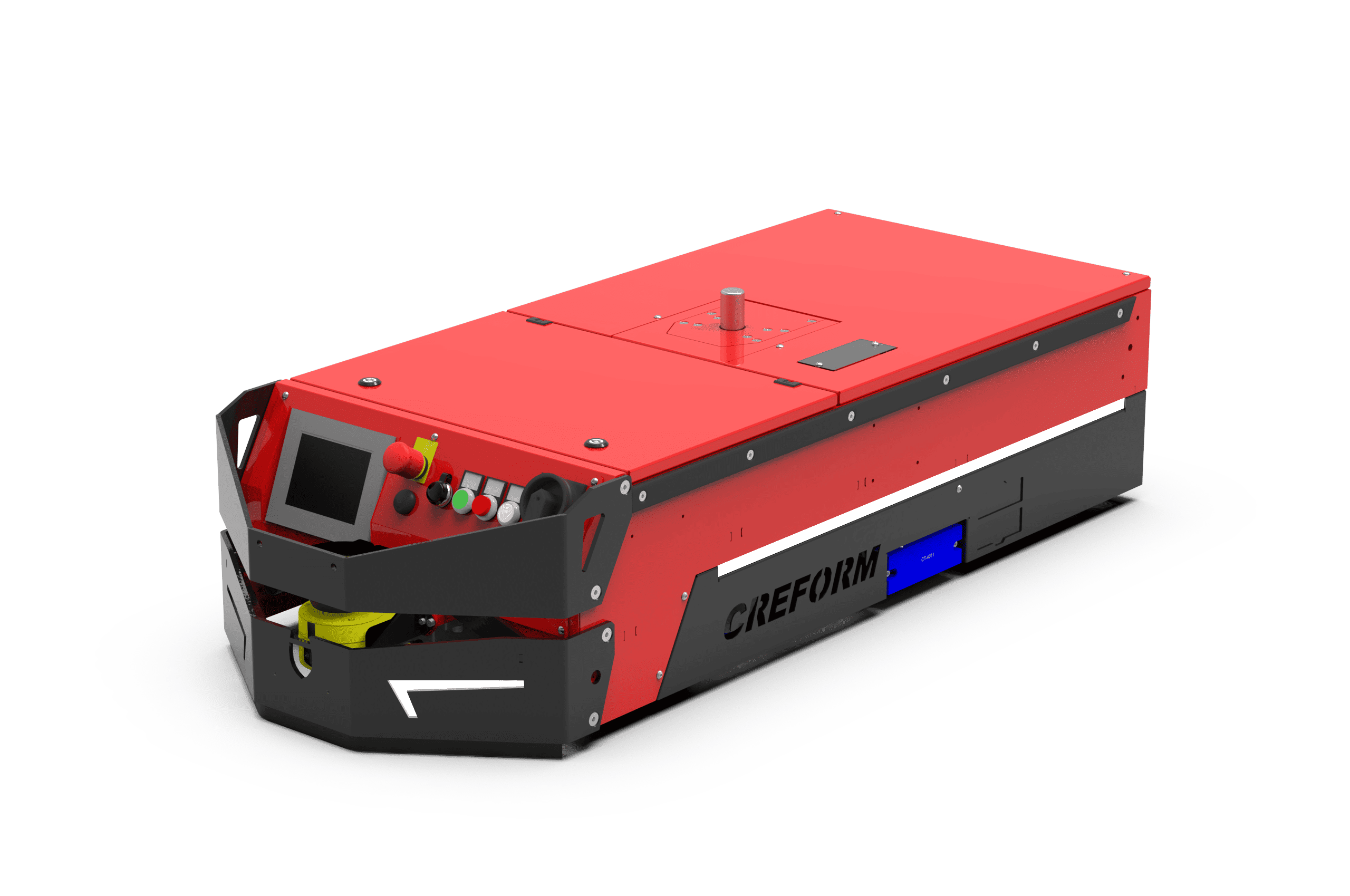

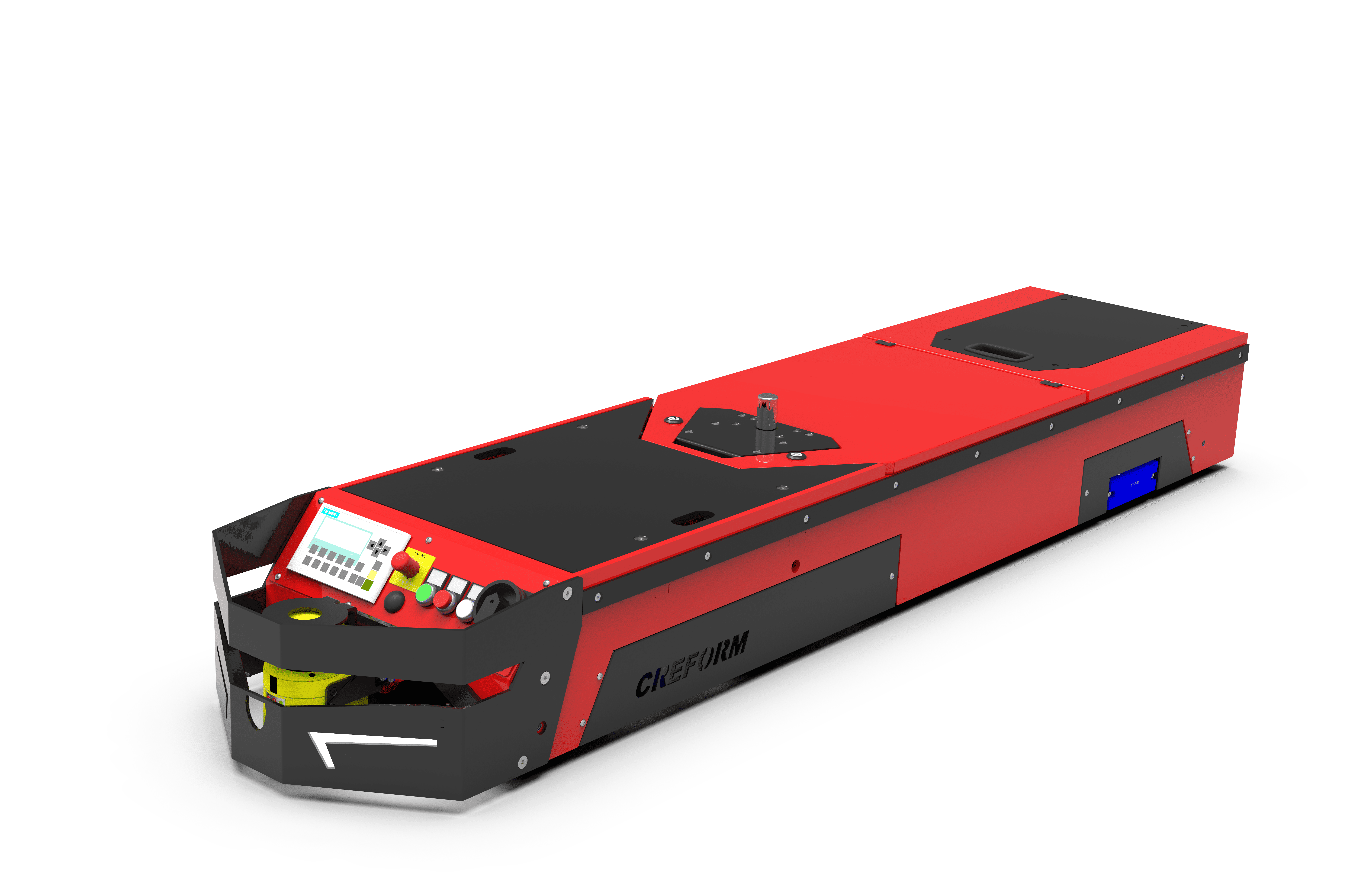

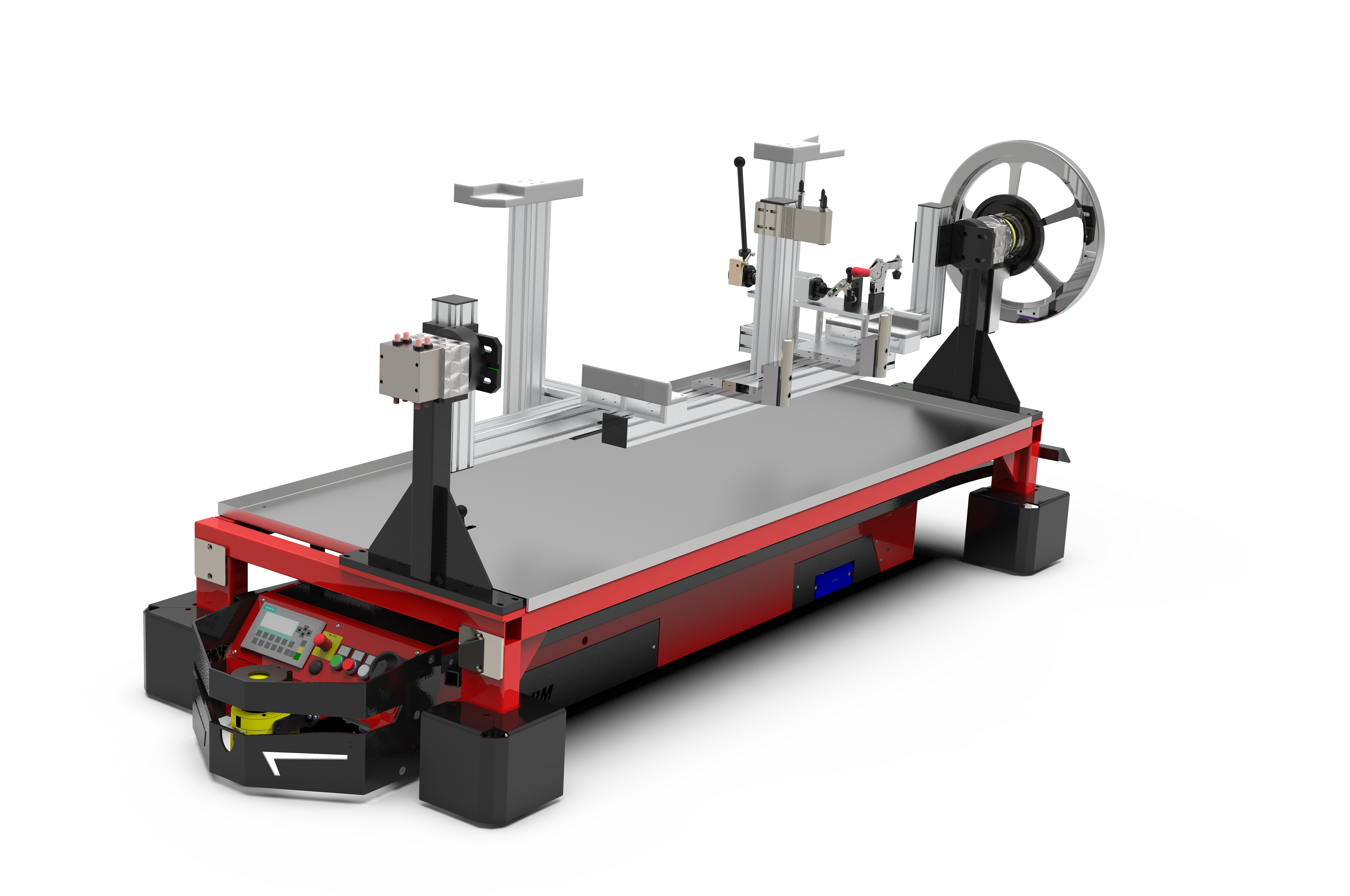

Automated guided vehicles (AGVs) or autonomous mobile robots (AMRs) are automated systems used for material handling and transport in production and logistics facilities. Our vehicles are usually guided by magnetic tapes on the ground or are free navigating. They are commonly used for tasks such as material handling, goods distribution, or just-in-time deliveries for logistics, manufacturing, warehousing, retail, or even hospitals. Our vehicles have a wide range of capabilities, including object and people detection and handling, as well as the competence to operate in complex environments.

NUMBERS & FACTS

Automated guided vehicles increase efficiency and reduce costs by automating the transport of materials and goods within a plant. Our vehicles are known for their durability and reliability due to the high quality components and modern technology. They are designed to withstand the most demanding conditions and, with their all-metal frames, are among the most robust and stable vehicles on the market. They are capable of operating 24/7, even in harsh environments, and have a proven track record of driving through customer facilities without damage.

With a lifespan of decades, investing in our vehicles is a timely decision for your company to secure its future. Our vehicles are a long-term investment that increase operational efficiency from minute one and pay dividends for many years to come.

MODELS & DIFFERENCES

| VM1 – Superflat | VM2 – Standard | VM2 – Vspec 1000 | VM2 – Vspec 2000 | VM3 – Bidirection | |

|---|---|---|---|---|---|

| Length | 1574 mm | 1301 mm | 1000 mm | 2000 mm | 1800 mm |

| Width | 480 mm | 553 mm | 553 mm | 450 mm | 553 mm |

| Height | 198 mm | 315 mm | 315 mm | 249 mm | 315 mm |

| Dead weight | 117-167 kg | 170-230 kg | 150 kg | 183 kg | 265 kg |

| Movable load | 500-800 kg | 500-1100 kg | 250 kg | 500 kg | 1000-1800 kg |

| Traction | 255-363 N | 260-540 N | 255 N | 260 N | 520 N |

| Speed | 0.05-0.83 m/s | 0.033-0.83 m/s | 0.07-0.83 m/s | 0.07-0.83 m/s | 0.05-0.83 m/s |

| Traverse direction | Uni- and bidirectional | Uni- and bidirectional | Uni- and bidirectional | Uni- and bidirectional | Omnidirectional |

| Navigation | Magnetic/ Natural Landmarks | Magnetic/ Natural Landmarks | Magnetic/ Natural Landmarks | Magnetic/ Natural Landmarks | Magnetic/ Natural Landmarks |

| Battery | Li-Ion 24 V 70 Ah | Lead- Gel 2×12 V 1000 Ah/ Li-Ion 24 V 62-120 Ah | Li-Ion 24 V 62 Ah | Li-Ion 24 V 62-90 Ah | Li-Ion 24 V 62-120 Ah |

| Charging system | Automatic (Mechanical/ Inductive), Manual (Battery change/ Charger) | Automatic (Mechanical/ Inductive), Manual (Charger) | Automatic (Mechanical/ Inductive), Manual (Charger) | Automatic (Mechanical/ Inductive), Manual (Charger) | Automatic (Mechanical/ Inductive), Manual (Charger) |

| Download data sheet | Download data sheet | Download data sheet | Download data sheet | Download data sheet |

INNOVATION & TECHNOLOGY

Our automated guided vehicles are equipped with advanced technology and ensure efficient and reliable material handling processes. Our product range includes magnetic track or free navigation options, so you can choose the solution that best fits your facility. In addition, we offer a choice of lead-acid or Li-ion battery technology to give you the best possible battery performance and life. There are generally four different ways to charge or power your vehicle. On the one hand, an AGV can be connected manually for charging, or a battery change can be performed. However, there is also the option of automatic charging with the help of charging contacts on the side or also on the floor. And this both via sliding contacts or inductive.

Our vehicles meet high quality standards, as confirmed by the acceptance by TÜV. We use only the best components, such as those from the manufacturers Siemens and Sick, so that our vehicles are always at the cutting edge of technology. With our range of vehicles, you can automate your material handling processes and increase your operational efficiency while ensuring the highest levels of safety and reliability.

Partnerships

INDIVIDUALITY & QUALITY

Our company offers a range of automated guided vehicles (AGVs) that can be customized to meet the unique needs of your facility. The full metal frame of our vehicles is also available individually in your desired colors and can therefore also be matched to your corporate branding.

The dimensions and characteristics of the automated guided vehicles can also be individually adapted to your requirements. CREFORM stands for customized and innovative solutions for internal material flow. Our goal is to increase the productivity and efficiency of our customers and give you a competitive edge in the market.

Our vehicles are by far the highest quality on the market and are developed and manufactured at our site in Baunatal (Germany). We use only robust materials that make our AGV more durable and stable, as well as renowned individual components that ensure the highest quality and technology.

In addition, we place great emphasis on safety and reliability. Our vehicles are subjected to strict quality controls to ensure that they meet the highest standards. With our focus on quality, innovation and customer satisfaction, we pride ourselves on helping our customers optimize their in-plant material flow and build long-term partnerships.

CONTACT

Do you have any questions? Write to us! We are looking forward to your message.