Production cells, also known as work cells, are nowadays indispensable workplace systems that can be individually designed, adapted, expanded or restructured according to the customer’s requirements. The advantage of Production cells in assembly lies above all in its efficiency and flexibility. Through the organization of the workspace in the Productioncells, all the necessary components, tools and materials are bundled in one place to perform specific assembly tasks. This enables an optimized work sequence and a reduction of transport routes, resulting in time and cost savings. Productionscells can additionally be perfectly supplemented by the use of automated guided vehicles (AGVs), to ensure the supply of materials to the Automate cell. All in all enable Productions cells in assembly provide an efficient, controlled and flexible production environment that leads to increased productivity, quality and customer satisfaction.

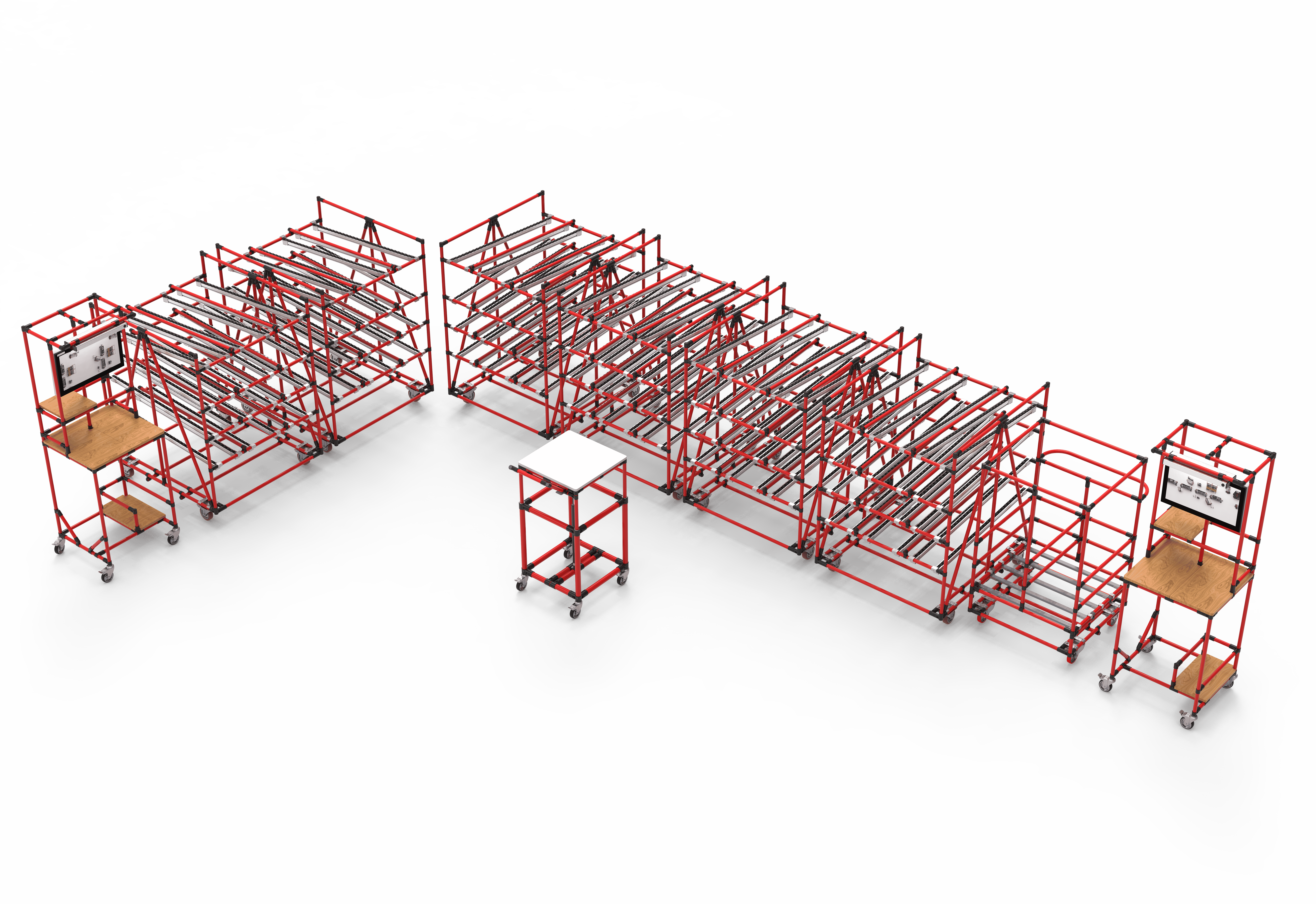

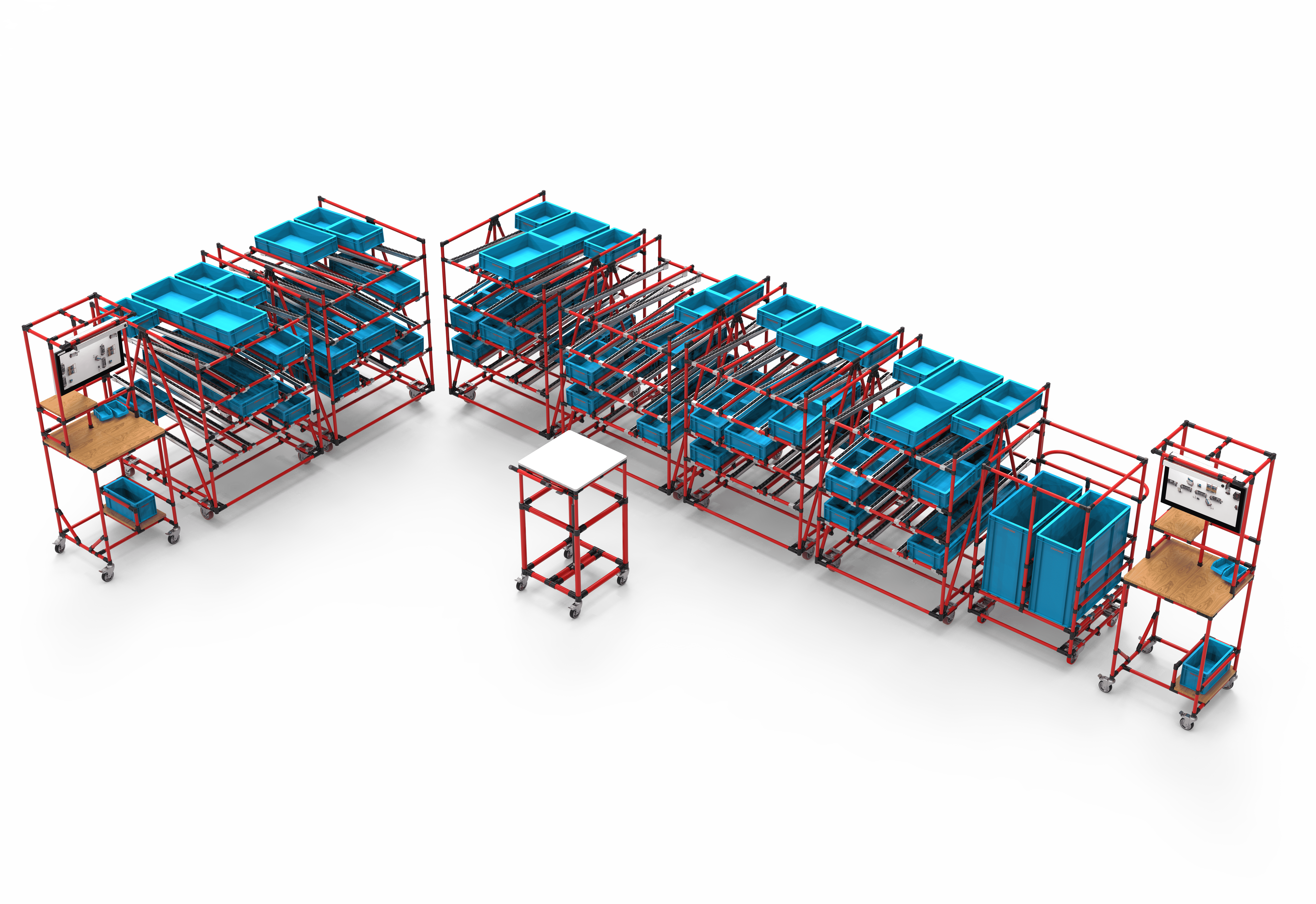

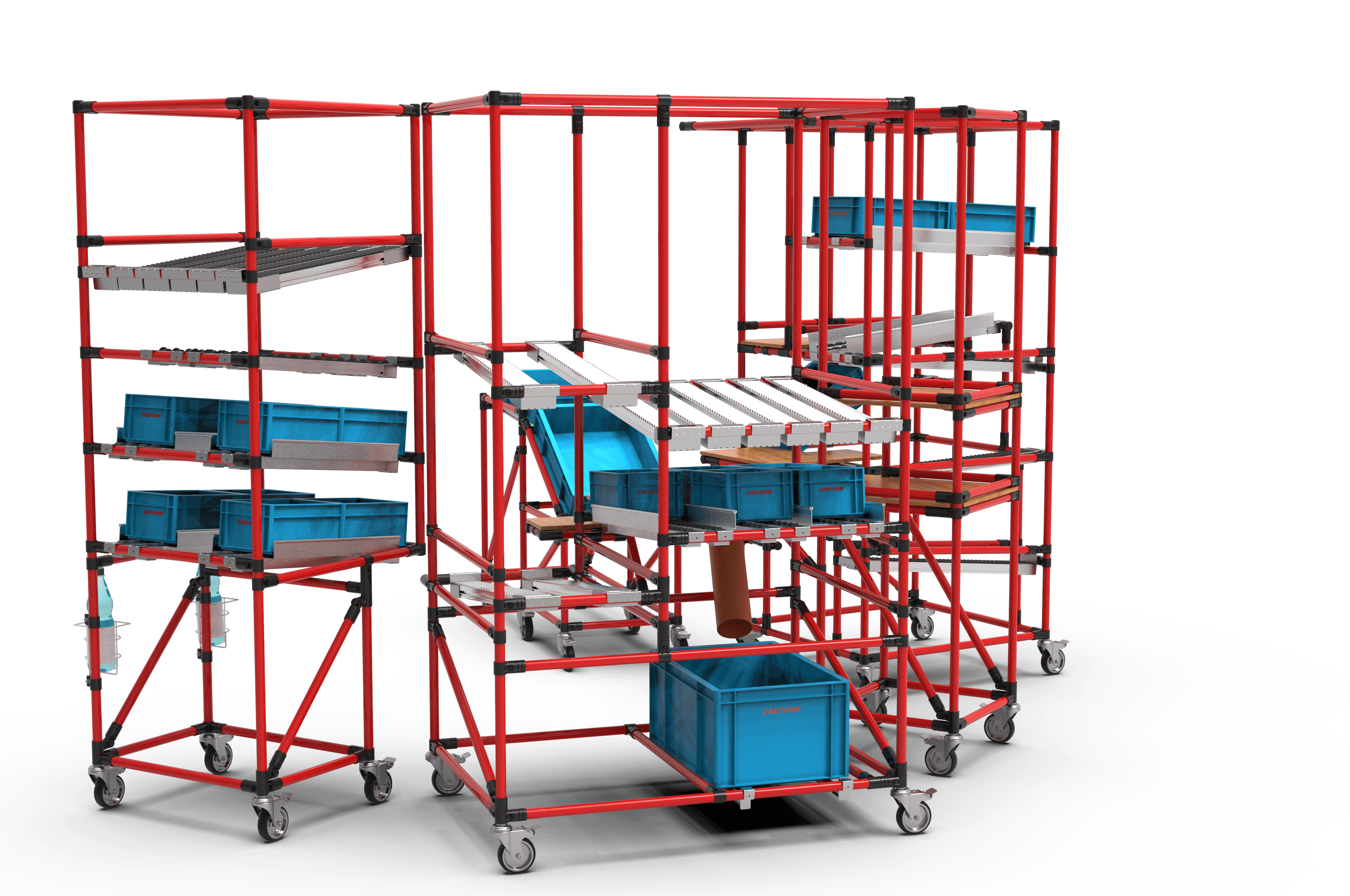

U-cells have a U-shaped arrangement of workstations, with workers located inside the U and performing work steps sequentially. The material is usually supplied from the rear of the U, while the Materials can be removed from the front. U-cells are particularly suitable for products with a higher number of variants or when production has to react flexibly to different product requirements. The close proximity of workstations in a U-cell promotes communication and the flow of information between employees, even in larger cells, resulting in improved collaboration.t. U-cells allow efficient use of the available space and reduced Material movement, as employees have to cover fewer distances. The benefits of U-cells include flexibility, improved communication and information flow, and efficient use of space.

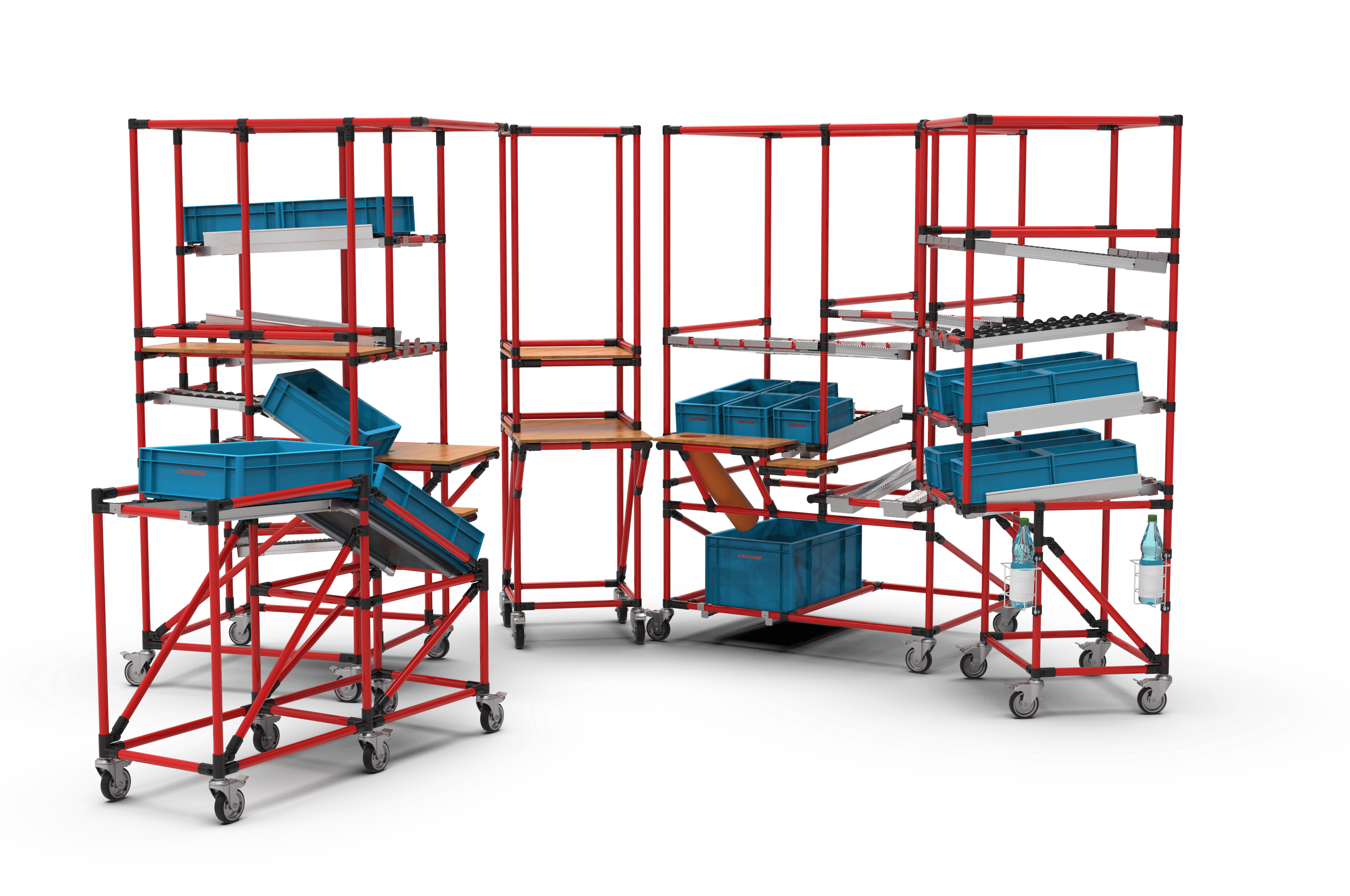

L-cells have an L-shaped workstation arrangement, with workers located on one side of the L and performing work steps along both sides of the L. The material supply takes place from the outer side of the L, while the materials on the inner page can be taken. L-cells are particularly suitable for products with a sequential workflow and a larger number of work steps. The L-shaped arrangement enables clear separation of the individual workstations and leads to improved work efficiency. L-cells provide good visibility and easy accessibility to workstations. The advantages of L-cells include a sequential workflow, good Overview and easy accessibility. The choice between U-cells and L-cells depends on the specific requirements of the production processes, the type of der Producte and the available space.

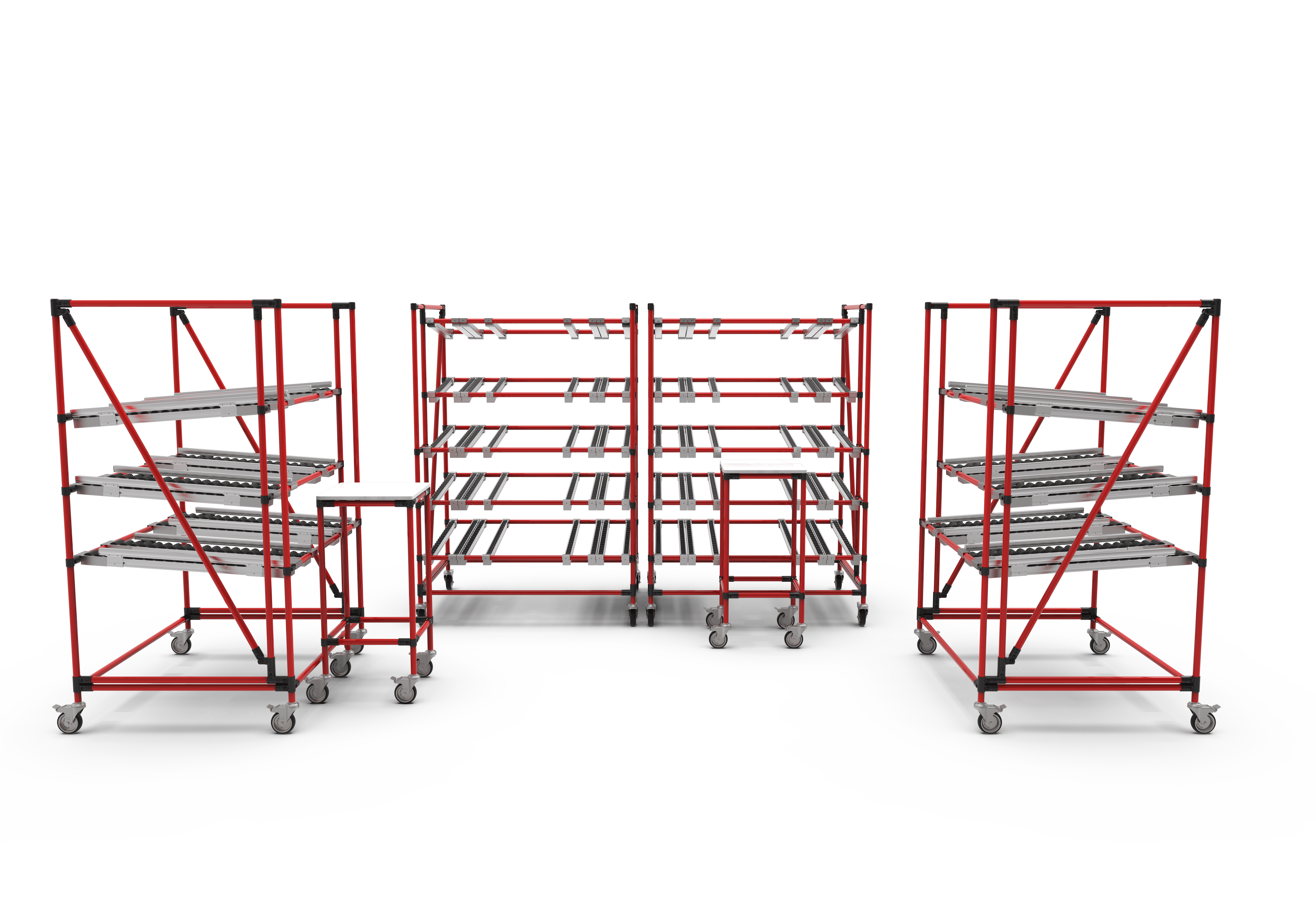

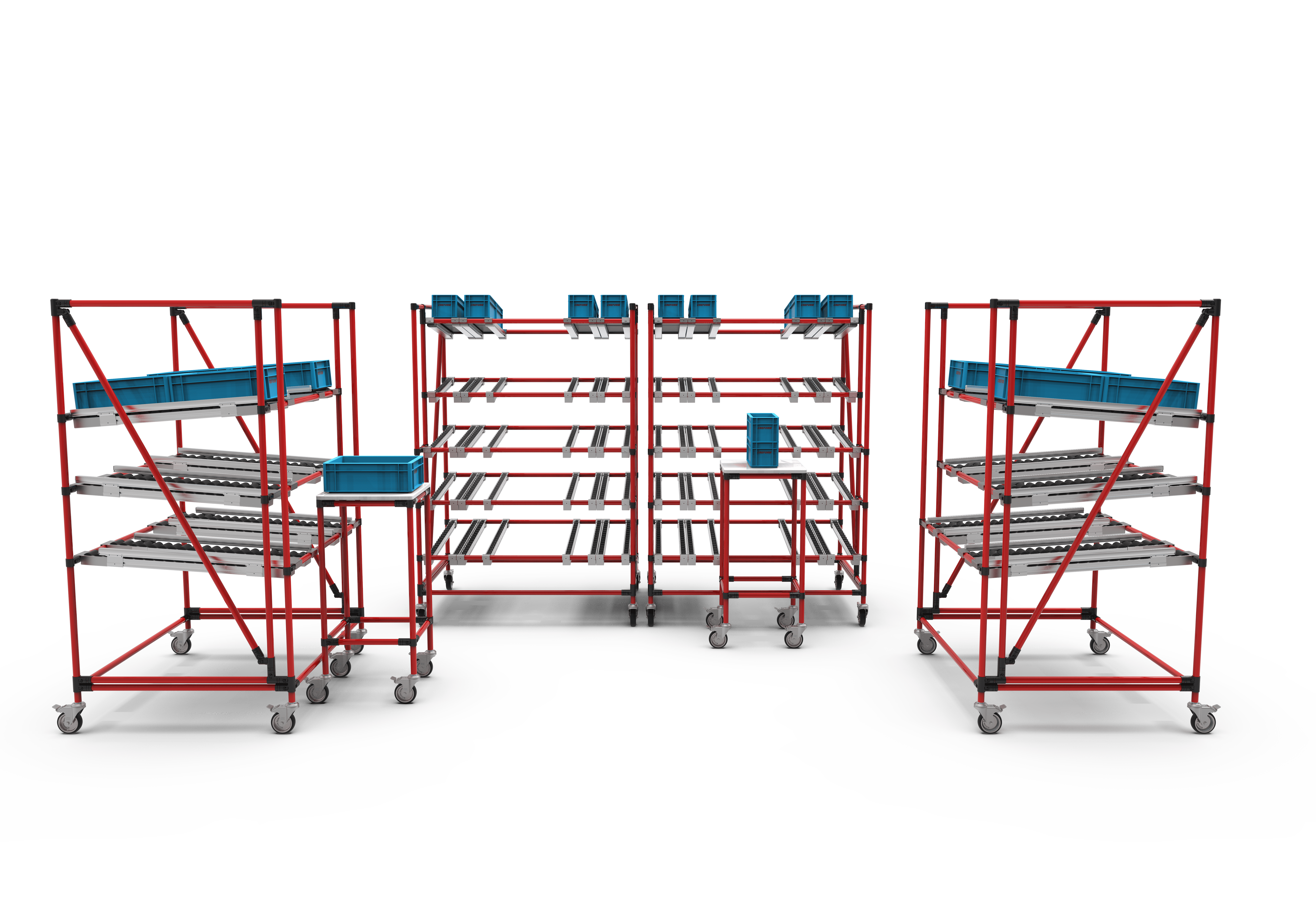

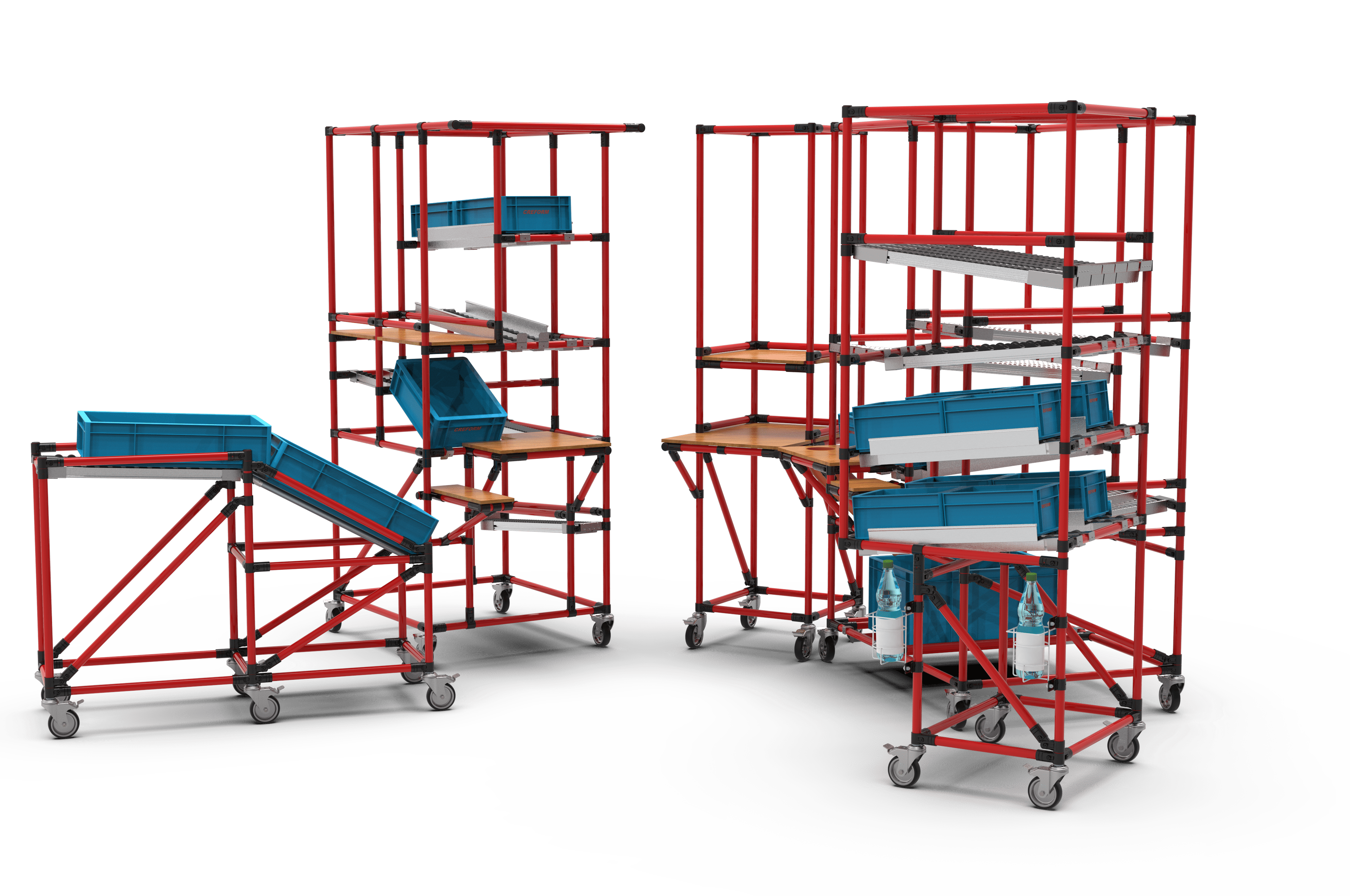

Assembly islands are smaller work areas in which specific assembly tasks or product groups are processed. The workstations consist of a combination of work tables, tool carts and shelves that are interconnected. Employees in assembly islands often specialize in a particular activity or product. Assembly islands made of tube plug-in systems offer flexibility because they can be adapted and restructured relatively easily to respond to changing product requirements or different manufacturing processes. Due to the close proximity of the employees to the assembly unit, quality checks can be carried out in real time and problems can be identified and rectified quickly. In addition, optimizing work ergonomics minimizes fatigue and accidents, resulting in higher productivity. The assembly island enables efficient flow, reducing lead times and inventory costs.

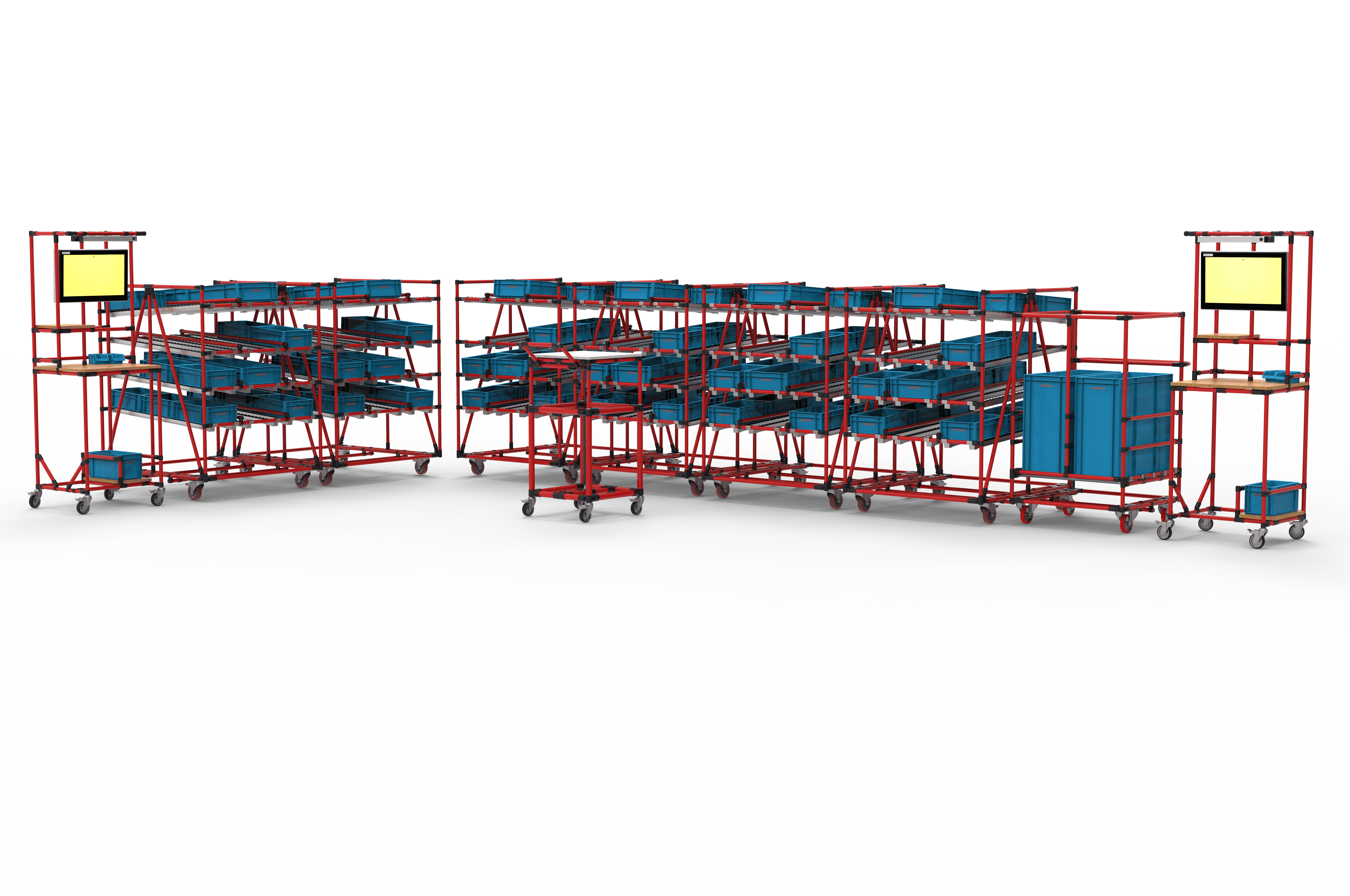

Assembly lines are longer production lines on which different assembly steps are carried out one after the other. Employees in assembly lines work along the assembly line and perform specific tasks at their assigned stations. Assembly lines are well suited for products with repetitive assembly steps and a high number of pieces. They enable continuous Vsupply and a uniform Materialflow. The structured flow in assembly lines allows processes to be optimized and productivity to be increased. Assembly lines can also be perfectly complemented by the use of automated guided vehicles (AGVs). The choice between assembly islands and assembly lines or even entire One-Piece-Flow cells depends on the specific requirements of the product, the production quantity and the desired flexibility.

One-Piece-Flow cells offer a number of advantages. Due to the continuous flow the and thus the throughput times are considerably are considerably shortened, since each part or product is processed individually from start to to completion is processed. The required product elements are supplied to the cell by the material supplier, from the outside. In this way, the advantages of flow production (ideal workplace design) and the advantages of workshop production, in terms of flexibility, are brought together. These sequential work processes result in faster delivery times and improved responsiveness to customer needs. At the same time, stock levels are minimized as no intermediate storage or stacking is required. Due to the continuous flow and the avoidance of bottlenecks or waiting times Bottlenecks are eliminated in the production process. This increases efficiency and improves the utilization of manpower. This leads to increased productivity and optimal use of available resources.

CONTACT

Do you have any questions? Write to us! We are looking forward to your message.