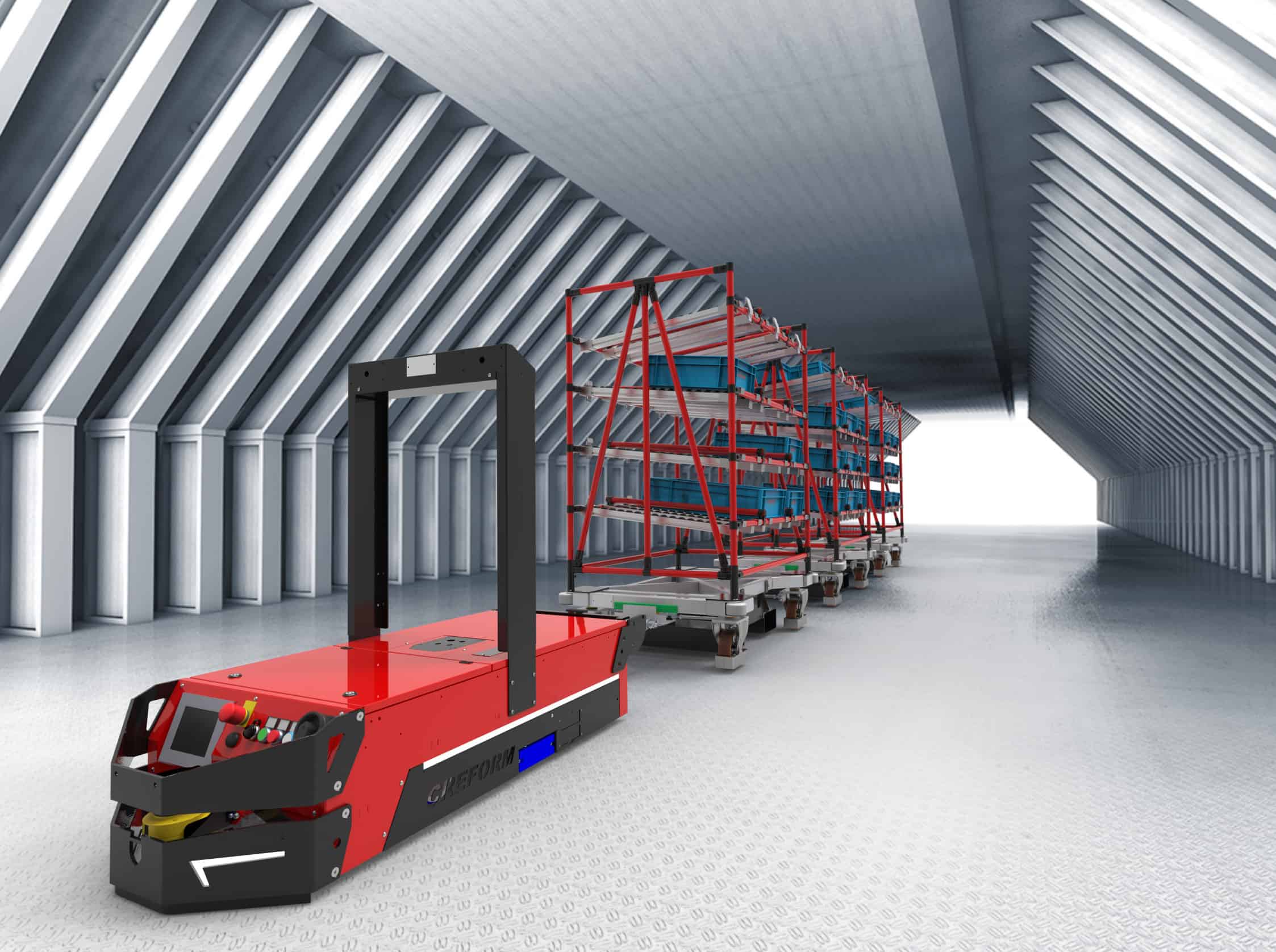

Automated Guided Vehicles (AGVs) are revolutionizing in-plant transportation in logistics, manufacturing, healthcare, retail and transportation, offering a wide range of applications in various industries such as automotive, food, medical and aerospace. A total of 25,000 CREFORM vehicles have been operating in a wide variety of companies worldwide since 1985. They improve efficiency, lower costs, reduce errors and help optimize workflows.

Possible applications

In logistics and warehousing, they optimize the flow of materials, shorten throughput times and reduce errors. This increases efficiency and reduces costs.

In the manufacturing industry, AGVs support the automatic supply of production lines, minimize bottlenecks and increase productivity.

In healthcare, AGVs can safely transport medicines, medical equipment and supplies and help optimize workflows.

In retail, AGVs automate in-plant transport, improve shelf replenishment, speed up order processing and increase customer satisfaction.

In transportation, AGVs ensure the smooth running of logistics centers and distribution centers, optimize traffic routes and enable punctual delivery.

Possible applications

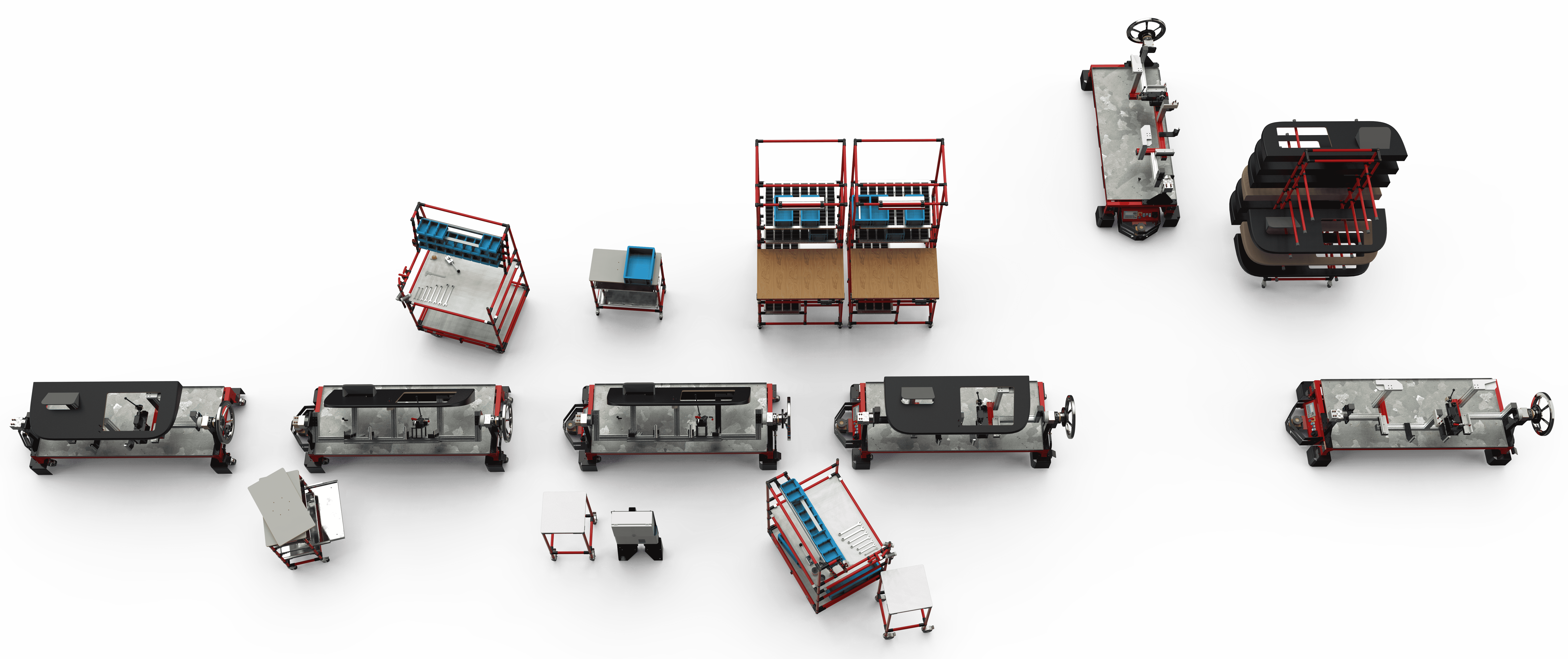

The vehicles are usually used to transport materials and goods within a production or logistics facility. They are programmed to follow a specific route, pick up items and deliver them to specific locations. They are able to carry heavy loads, increase material handling efficiency and reduce the need for manual labor.

The vehicles can also be used as mobile production and assembly lines, allowing greater flexibility in production processes. They can be programmed to perform specific tasks, such as product testing, while traveling from one station to the next, reducing the need for manual labor and increasing operational efficiency.

The vehicles can also be used in a milkrun (route train) system, where they travel along a set route to multiple production or warehouse locations, picking up and delivering goods as needed. This system is designed to increase the efficiency of material handling processes, reduce the need for manual labor, and allow personnel to focus on other value-added tasks.

In Goods-To-Person systems, vehicles bring goods directly to staff, eliminating the need for employees to drive to a storage location. This system is designed to increase the efficiency of material handling processes and reduce the need for manual labor. The vehicles are programmed to bring specific items to specific people, reducing the time and effort required to locate and transport goods.

CONTACT

Do you have any questions? Write to us! We are looking forward to your message.