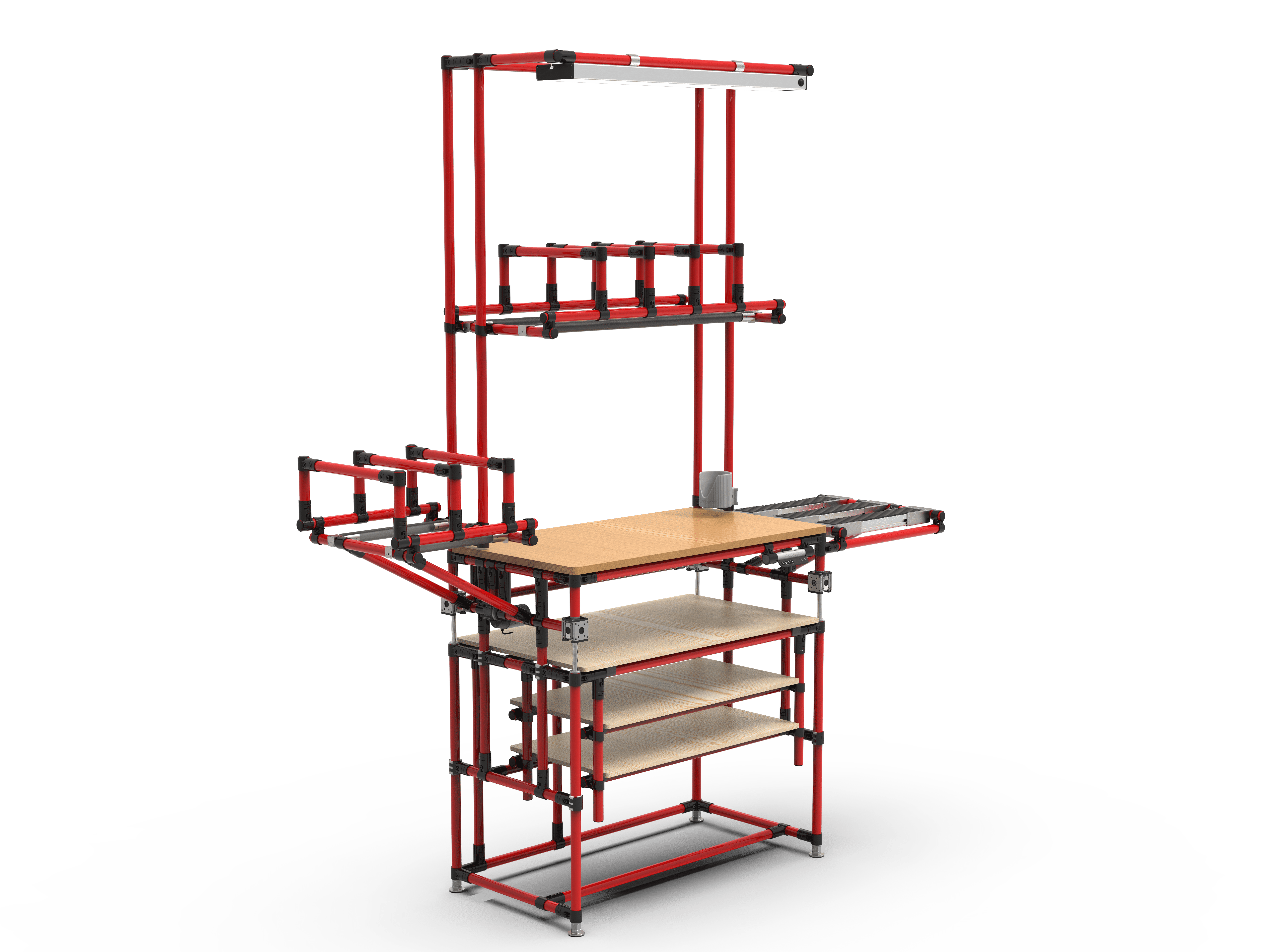

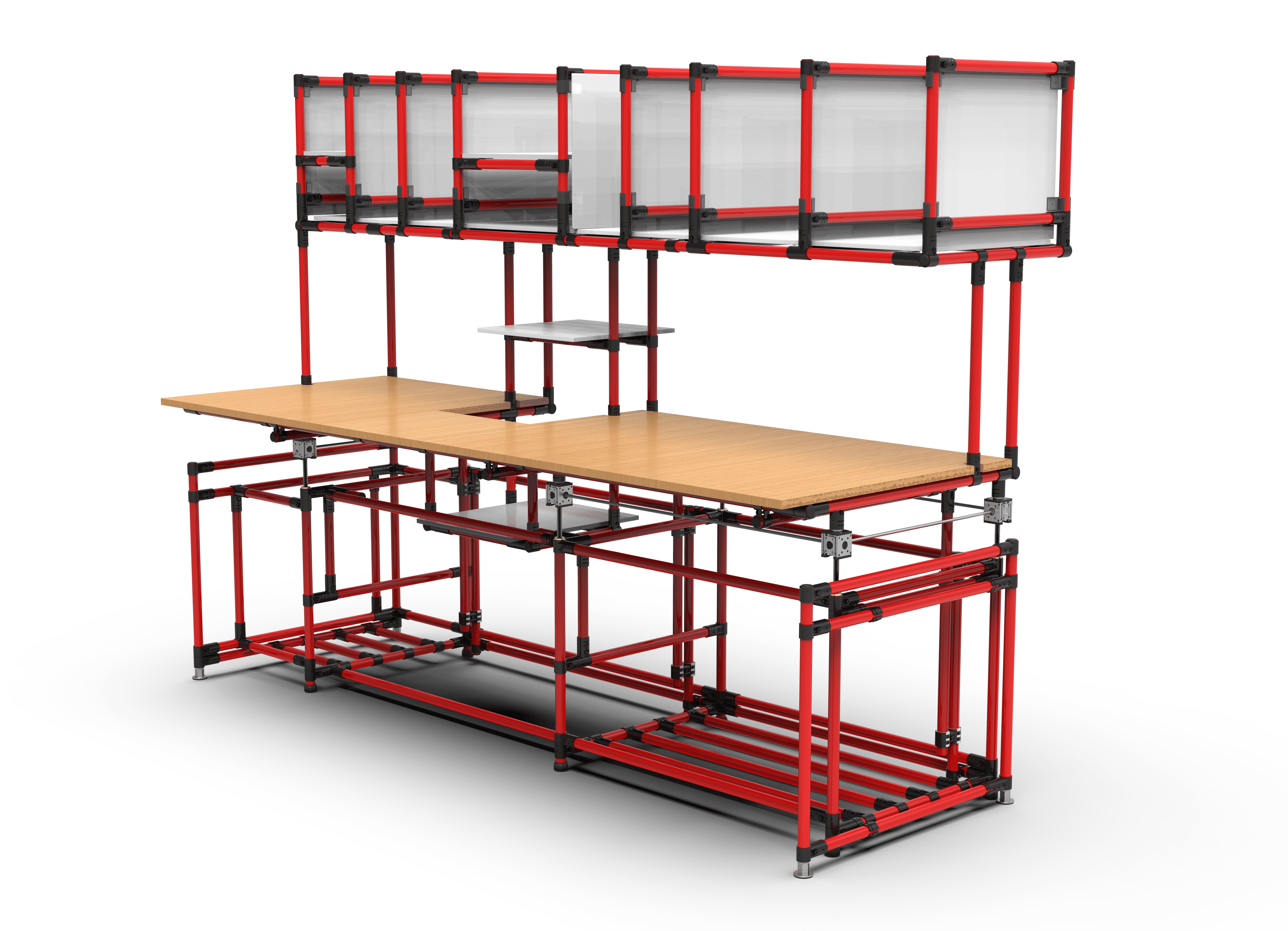

CREFORM relies on lean management for lean production and efficient work organization. Custom-fit and ergonomic workstations play an important role in this. Whether in production, manufacturing, design, assembly, testing, shipping, logistics or CAD – customer-specific and customized solutions are definitely in demand.

Our goal is to create demand-oriented and durable solutions that meet individual requirements. CREFORM’s modular system makes it possible to design workstations that allow for both standing and sitting activities. Here, electrical and manual height adjustment represent important aspects for ergonomics. Optionally also available in ESD design, this equipment is used without any problems in work areas where sensitive electronic devices or measuring instruments are used. Our modular systems allow flexible adaptation to changing requirements.

Ergonomic work tables and workbenches are critical elements in an efficient and healthy work environment. An ergonomic work table can help prevent strain and injury to the body, thus increasing performance. Here are workbenches from a pipe & joint system particularly popular. These are modular and can be customized to meet the needs of the job and the employees. Lean management also ensures that processes are efficient and lean, to increase the value-added share and minimize waste.

ESD-capable workstations play an important role when it comes to protecting electronic components from electrostatic discharge. With ESD-equipment, such as work tables, shelves and material trolleys, ensures an ESD-free work environment is ensured.t. Also in this case, workbenches made of pipes & joints are particularly popular because of their modularity and adaptability to the requirements of the work. ESD-capable pipe & joint systems offeran additional advantage that electrostatic discharges are reliably dissipated. This prevents damage to the sensitive electronic components. Alsooperating equipment as setup trolleys, tool and cleaning trolleys, as well as infoboards are also an important component in many production environments and should be ESD-capable here to ensure a safe working environment. Through lean management, attention is also paid here to efficient and lean processes in order to avoid waste.

Height-adjustable tables, such as manual or electric lift work tables, are indispensable in industry and production to ensure optimized ergonomics in the line and island production . Both manual (with crank) and electric height adjustment are possible. This type of adjustment can help to make the work tables modular and individually adapted to the requirements of assembly, production, logistics or packaging. Everything can be customized. Height-adjustable desks thus contribute to the health of employees and promote work performance.

In order to achieve optimum work performance in the field of Packing a high degree of ergonomics and lean measures are required. Our approach aims to minimize waste, optimize flow and ensure efficient use of resources. These include, for example, the 5S method for organizing and tidying the workplace, as well as the application of standardized work instructions, to ensure uniform and effective operation. An optimized workplace can help optimize packaging processes, leading to a reduction in waste, working hours and costs, as well as das employees are physically relieved and can therefore work more efficiently and healthier.

We believe that an ergonomic assembly station is an important part of efficient production. This is because a workstation adapted to the operator’s needs can help a single person manufacture diverse products using tools, equipment and machinery – without unnecessary walking, buffers and intermediate storage. The required product elements are fed to the assembly station from the outside, opposite the operator, by the material supplier so that the operator can grip them ergonomically. Our assembly stations are designed to optimize your production and relieve your employees.

CONTACT

Do you have any questions? Write to us! We are looking forward to your message.